Effective Use of Concrete

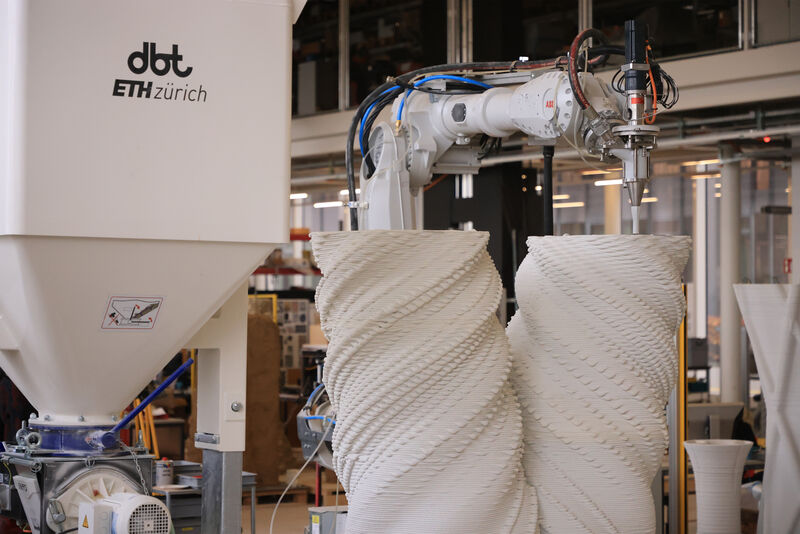

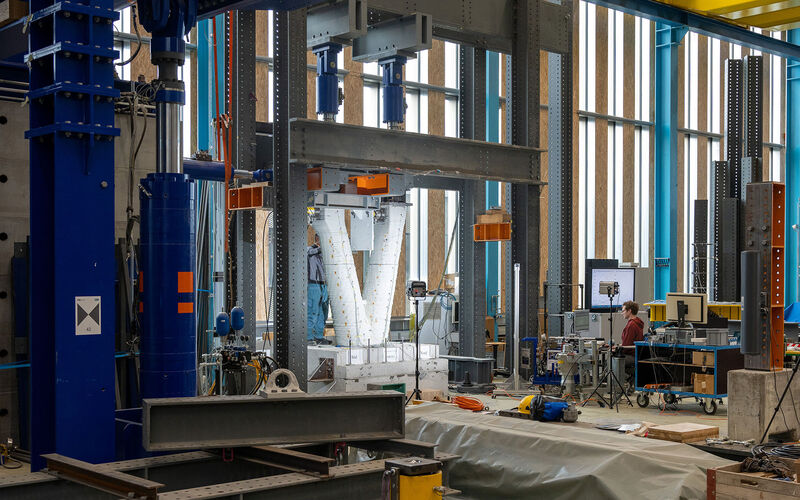

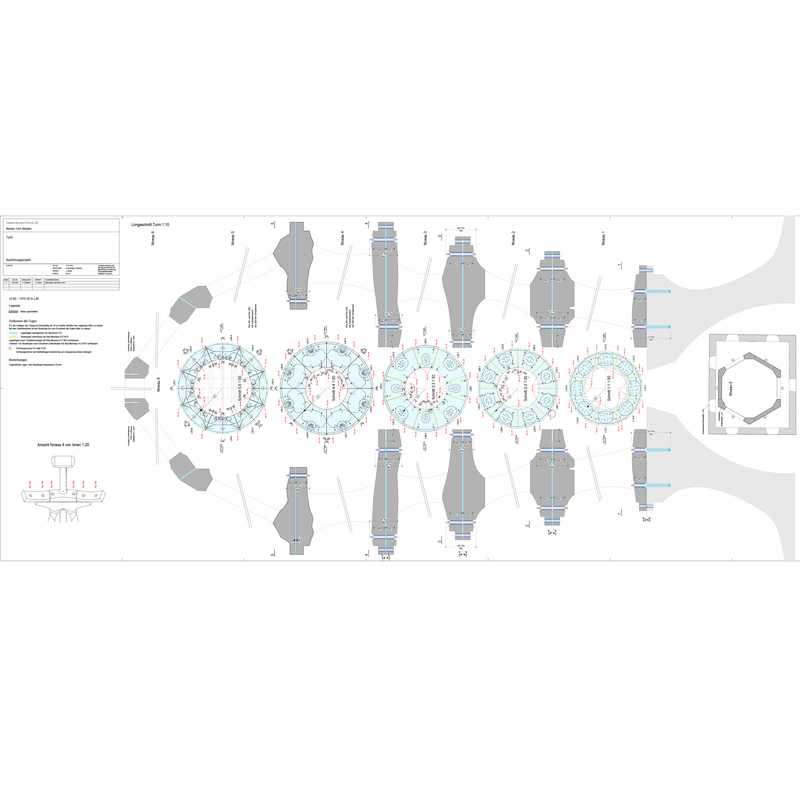

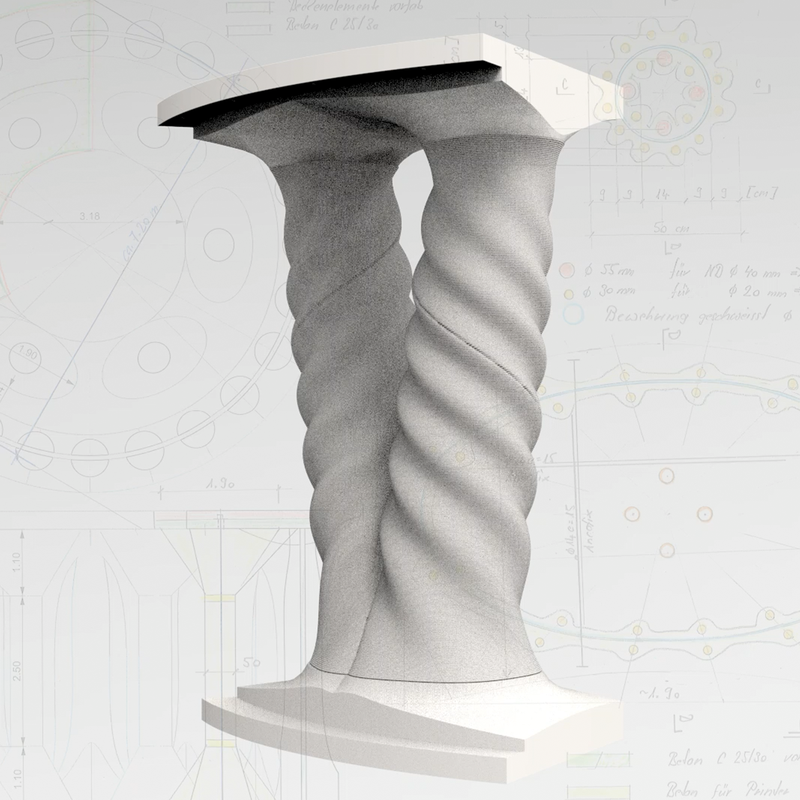

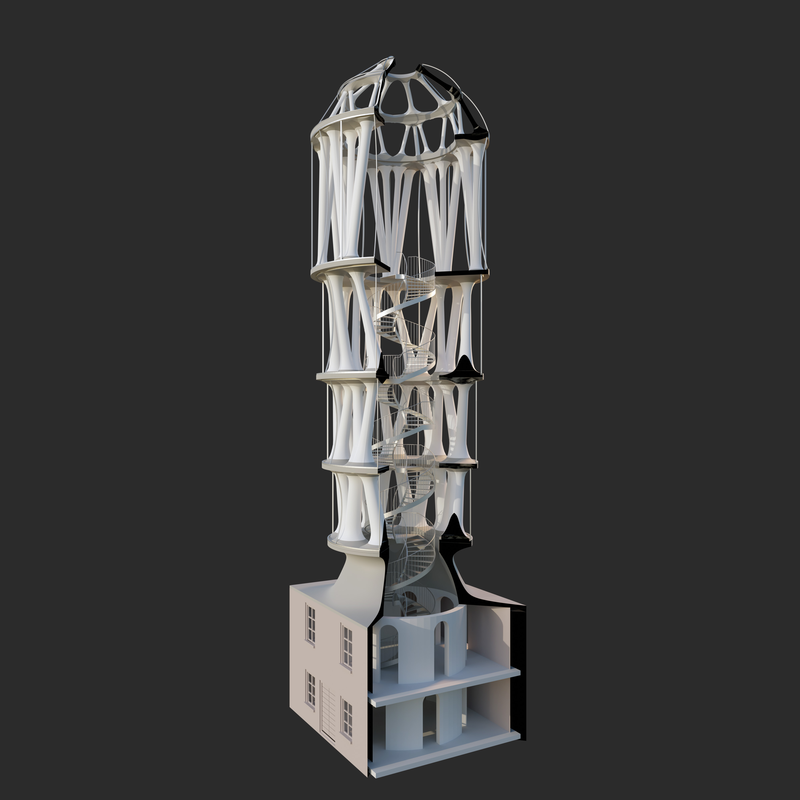

For the first time, a multi-floor building features 3D-printed bespoke structural columns with integrated steel reinforcement and ornamented outer skin. Each column branch is prefabricated through 3D printing, eliminating the need for formwork and reducing material consumption through its hollow, thin-shell design. Base and capital of the columns are cast in 3D printed, fully recyclable formwork, embedding details for dry connections, allowing non-destructive dis- and reassembly of the tower.

Material-Specific Innovations

The 3D-printed concrete contains a stabilizing admixture and an accelerator for rapid hardening, which allows free-form elements to be 3D-printed in layers fast and high with large overhanging details. The most significant innovation of the process is that the reinforcement is placed while the concrete is being 3D printed. This is done using two robots working together: one continuously applies the fresh concrete, while the other places the reinforcement horizontally between the layers.

Interdisciplinary Approaches

Tor Alva demonstrates interdisciplinary research from the NCCR DFAB of ETH Zurich in computational design, digital fabrication, structural engineering, and material science.

It also showcases the successful bidirectional knowledge transfer between local and global industry partners and research institutions. Last but not least, architecture and engineering are paired with the activities of the regional non-profit organization Origen, merging science and art towards a digital building culture.

Site-Specific Design

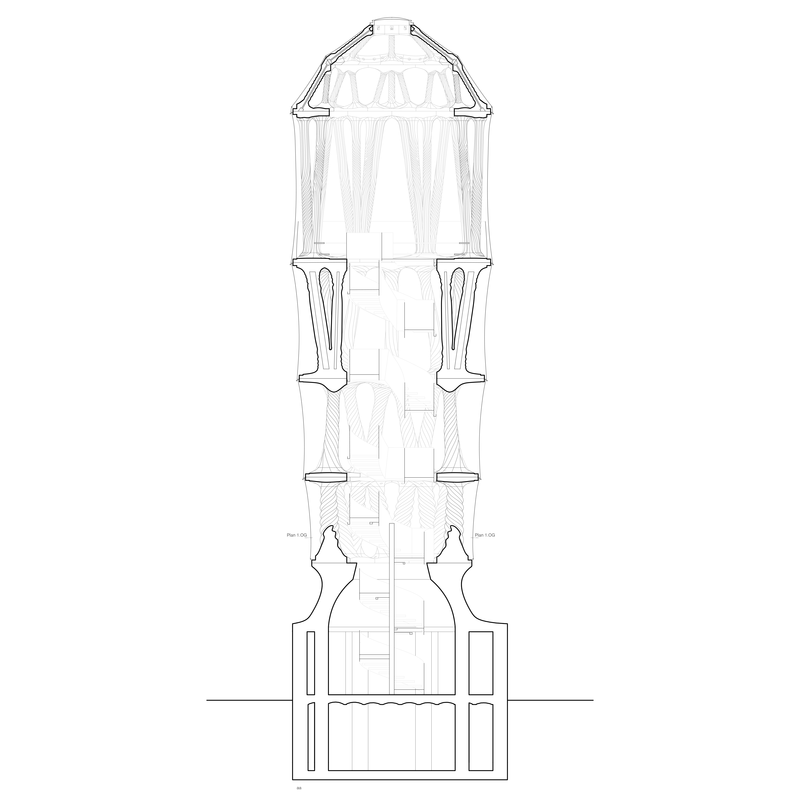

The cultural foundation Nova Fundaziun Origen creates a unique cultural venue for events revitalizing the region of Mulegns in the Swiss Alps. The tower’s richness of form pays homage to the craftsmanship of the canton’s Baroque-era master builders and former inhabitants, working as plaster craftsmen and confectioners, whose work shaped the region’s architectural identity. At night, the tower and its organic openings act as a glowing lantern along the historic Julier Pass.

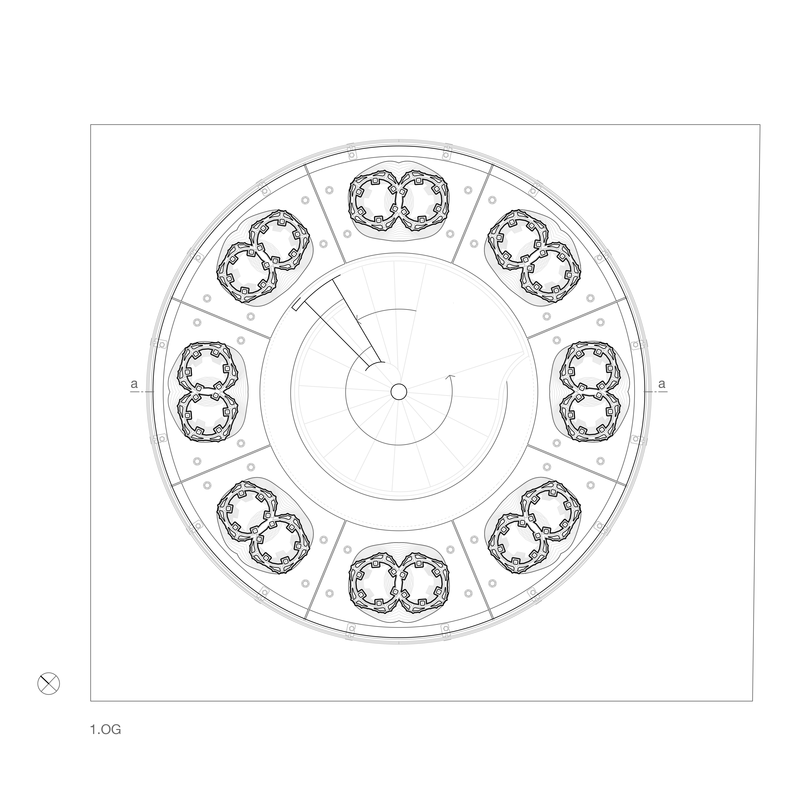

Design and Spatial Concept

Each column is digitally designed with three geometric scales from branching macro-structure to material-driven ornament demonstrating digital craftsmanship. On lower floors, robust columns create enclosed, intimate spaces, while upper floors feature slender columns, creating a lighter, airier feel. The columns evolve with elevation: on the ground floor, they are broad and 3.4 meters tall, while on the top, they rise to 6 meters, culminating in a cupola with an intricate branching structure.

Thoughtful Structural Design

Tor Alva showcases the structural potential of 3D concrete printing for multi-story buildings, including a 7m wide spanning cupola. The modularisation and prefabrication allow non-destructive disassembly. The organic form incorporates branching columns with locally adapted cross-sections that effectively resist lateral forces with minimal material use. The structural design harmonizes 3D printing with integrated reinforcement, enabling individually optimized geometries.

Comprehensive Sustainability

Robotic concrete extrusion increases the degree of automation, eliminates the need for molds, and places concrete precisely where required, reducing 40% of material compared to conventional casting. Key contributions to sustainable building strategies include thin-shell 3D-printed structural elements, and modular construction enabling disassembly and future reuse. The sustainability impact goes beyond the single project as it is a key component in the revitalization strategy for the region.